AEM FLEX120水素製造装置の特徴

-

迅速な納品あなたのAEM Flex120は到着後、わずか数ヶ月でグリーン水素生産を開始できる。私たちはシンプルな計画を主張し、比較的短い納期であなたのグリーン水素試行プロジェクトが迅速に展開できることを保障する。

-

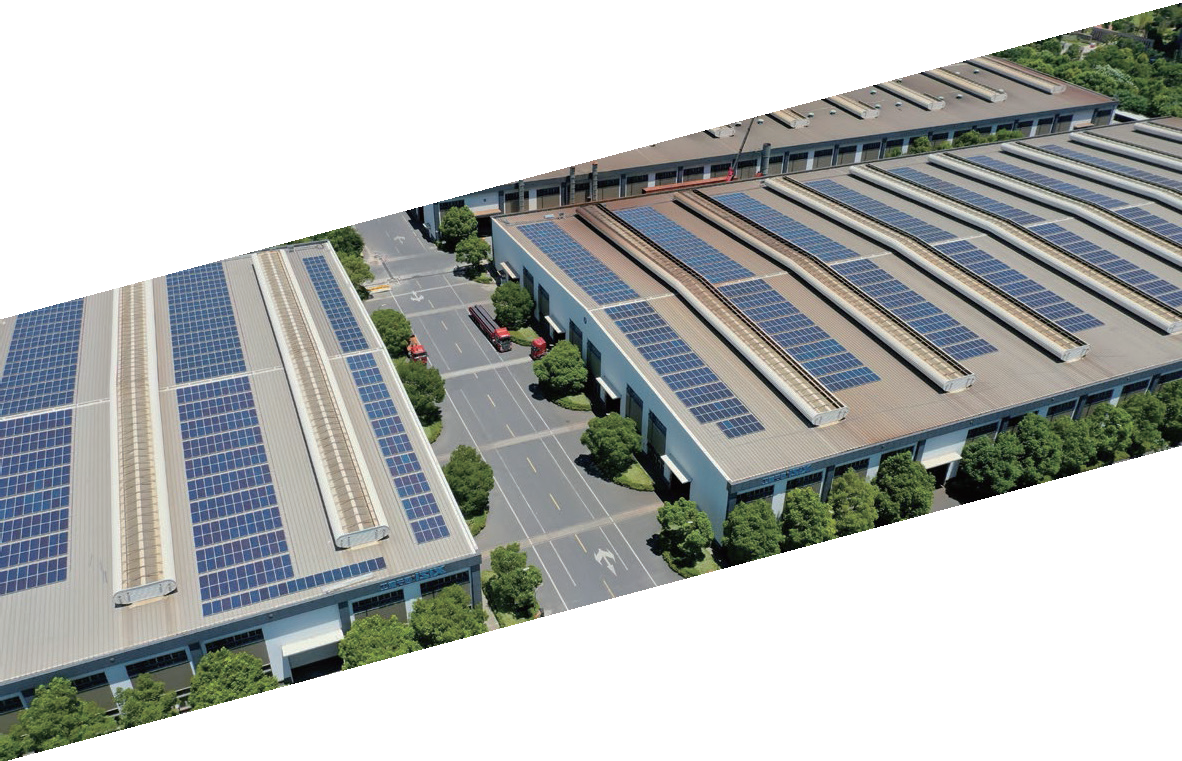

簡素化された統合私たちの無コンテナこじ開け式電解槽は、既存のエネルギープロジェクトに迅速かつシームレスに統合され、大量の敷地やシステム改造を必要とせずに、水素生産能力を増加することができる。

-

オーダーメイドAEMボルタパイルのクラスターの数を選択し、必要な水素生産量を精確に獲得する:70kWから480kWまでの間。もし小規模から始めると、電解槽の生産能力を後から増やすこともできる。

運転条件

-

8:1調節率

-

12% –100%運行の柔軟性

-

5 – 55 °CH₂出口温度

仕様パラメータ

| H₂定格流量 | 25 Nm³/h (53.9 kg/24h) |

| H₂出口圧力 | 35bargに達する事ができる |

| H₂純度 | 99.95%はモル分数で表示され、-30°Cの露点に等しい |

| H₂純度 (乾燥機を選択する) | 99.999%はモル分数で表示され、-65°Cの露点に等しい |

| 定格パワー損耗 | 120kW寿命サイクル開始 (BOL |

| 電圧 | 3 × 400 VAC ± 10 % |

| 周波数 | 50/60 Hz ± 10 %; THD < 5 % |

| H₂O正常消耗 | 23L/h工業純水 |

| H₂O入口品質 | 少なくともASTM D1193-06型IVまたは推II型またはIII2型² |

| ウォームスタート時間 | 0~100%100秒以内 |

| コールドスタート時間 | 0~100%30分以内 |

| 外形寸法 | 3.2×2.5×3メートル (長さ×幅×高さ) |

典型的な応用

-

貯蔵するピーク調整から長期貯蔵戦略まで、本電解槽は過剰エネルギーを利用して水素を生産する多機能ソリューションを提供した。 会社は脱炭素と自給自足計画を行動に移すことができる エネルギー開発者は電力網とコミュニティに最大の価値をもたらします。

貯蔵するピーク調整から長期貯蔵戦略まで、本電解槽は過剰エネルギーを利用して水素を生産する多機能ソリューションを提供した。 会社は脱炭素と自給自足計画を行動に移すことができる エネルギー開発者は電力網とコミュニティに最大の価値をもたらします。 -

工業原料グリーン水素は灰水素の代わりに工業原料として、食品、アンモニア、メタンなどの化学品などの製造に用いられている。 当社のAEM Flex120は工業企業がグリーン水素の生産と使用を迅速に試行するのを助けて、急速な拡張と全面的な代替のための扉を開いた。

工業原料グリーン水素は灰水素の代わりに工業原料として、食品、アンモニア、メタンなどの化学品などの製造に用いられている。 当社のAEM Flex120は工業企業がグリーン水素の生産と使用を迅速に試行するのを助けて、急速な拡張と全面的な代替のための扉を開いた。 -

工業用熱天然ガスを工業用熱として使用している会社はグリーン水素ガスに切り替えて溶鉱炉に火をつけている。 AEM Flex 120は、レンガ、セラミック、プラスチックメーカーがガス混合によって運用コストを徐々に削減し、化石燃料への依存を解消し、独自の持続可能な発展リーダーシップを確立するために努力しています。

工業用熱天然ガスを工業用熱として使用している会社はグリーン水素ガスに切り替えて溶鉱炉に火をつけている。 AEM Flex 120は、レンガ、セラミック、プラスチックメーカーがガス混合によって運用コストを徐々に削減し、化石燃料への依存を解消し、独自の持続可能な発展リーダーシップを確立するために努力しています。 -

水素ステーションのデモンストレーション当社のフレキシブル電解槽は効率と拡張性を高めるために設計されており、変動する再生可能エネルギーを利用して現場で水素製造を行い、パイロットプロジェクトと次の段階の成長のニーズを満たすことができる。 外部供給業者への依存を減らし、持続可能な水素駆動の未来に道を開く。

水素ステーションのデモンストレーション当社のフレキシブル電解槽は効率と拡張性を高めるために設計されており、変動する再生可能エネルギーを利用して現場で水素製造を行い、パイロットプロジェクトと次の段階の成長のニーズを満たすことができる。 外部供給業者への依存を減らし、持続可能な水素駆動の未来に道を開く。