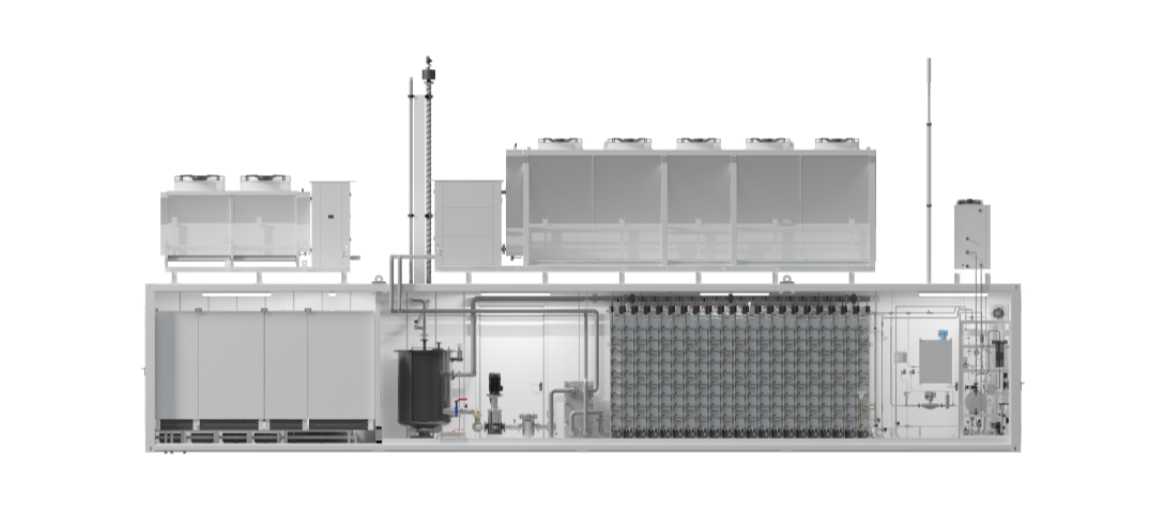

Characteristics of AEM electrolysis module

-

Quick startDeploy MW-scale green hydrogen without the wait. This ready-made electrolyser offers you quick and easy setup so you can focus on making and using your green gas. It is designed to unlock both on-grid & decentralised appli- cations, delivering on-site hydrogen where you need it.

-

Multiple AEM heartsAEM Stack electrolyser cores are the heart of our green hydrogen generators. Our AEM Nexus has hundreds, mounted in strings of 10. Each string ramps up or down separately to get the most out of your renewable energy at any energy load, giving massive system flexibility.

-

Maximum uptimeResilience you can rely on: The modular design removes bottlenecks and single points of failure, all the way from AEM stacks to balance of plant. Enjoy maximum uptime, even when servicing: Work on individual strings of AEM Stacks while others still make green hydrogen.

Operating Condition

-

-15℃~+35℃Ambient operating temperature

-

3% – 100%Operational flexibility

-

5 – 55 °CH₂ outlet temperature

Specifications

| H₂ nominal flow | 200 Nm³/h (428kg/24h) |

| H₂ outlet pressure | Up to 35 barg (507.63 psig) |

| H₂ purity | 99.95% in molar fraction |

| H₂ purity with optional dryer | 99.999% in molar fraction |

| Nominal power consumption | 960 kW Beginning of life (BOL) |

| Voltage | 3 × 400 VAC ± 10 % |

| Frequency | 50/60 Hz ± 10%; THD < 5% |

| H₂O nominal consumption | 190 L/h (50.19 gal/h) Purified water |

| H₂O inlet quality | Minimum ASTM D1193-06 Type IV or recommended Type II or Type III |

| Hot startup time | 0 ~ 100% in 100 seconds |

| Cold startup time | 0 ~ 100% in 20 minutes |

| Dimensions | 12000*2428*2896mm(L × W × H) |

| Weight | ≈ 35 tons |

Typical applications

-

Provide renewable energy storage for developers, utilities and communitiesGreen hydrogen storage is used to optimize fluctuating renewable energy, so as to realize power grid balance, microgrid, power restriction and green natural gas supply. Unlock the application of energy conversion, commercial supply, heating and cooling.

Provide renewable energy storage for developers, utilities and communitiesGreen hydrogen storage is used to optimize fluctuating renewable energy, so as to realize power grid balance, microgrid, power restriction and green natural gas supply. Unlock the application of energy conversion, commercial supply, heating and cooling. -

Industrial application of replacing gray hydrogen and natural gasIt can be used in green ammonia production, semiconductor carrier gas, green steel blast furnace injection, renewable methanol, biofuel and biogas production, glass annealing or as chemical raw materials.

Industrial application of replacing gray hydrogen and natural gasIt can be used in green ammonia production, semiconductor carrier gas, green steel blast furnace injection, renewable methanol, biofuel and biogas production, glass annealing or as chemical raw materials. -

Hydrogen refueling stations for private fuel cell vehicles or commercial usersWith our AEM Nexus, you can easily replace gray hydrogenation, switch from traditional internal combustion engine vehicles or manufacture your own synthetic fuel and electronic fuel.

Hydrogen refueling stations for private fuel cell vehicles or commercial usersWith our AEM Nexus, you can easily replace gray hydrogenation, switch from traditional internal combustion engine vehicles or manufacture your own synthetic fuel and electronic fuel. -

Energy self-sufficiency of enterprises and institutionsUse green hydrogen to release standby energy, replace polluted diesel generators, study hydrogen solutions and energy independence, achieve complete energy self-sufficiency, and unlock grid-connected and decentralized microgrids.

Energy self-sufficiency of enterprises and institutionsUse green hydrogen to release standby energy, replace polluted diesel generators, study hydrogen solutions and energy independence, achieve complete energy self-sufficiency, and unlock grid-connected and decentralized microgrids.