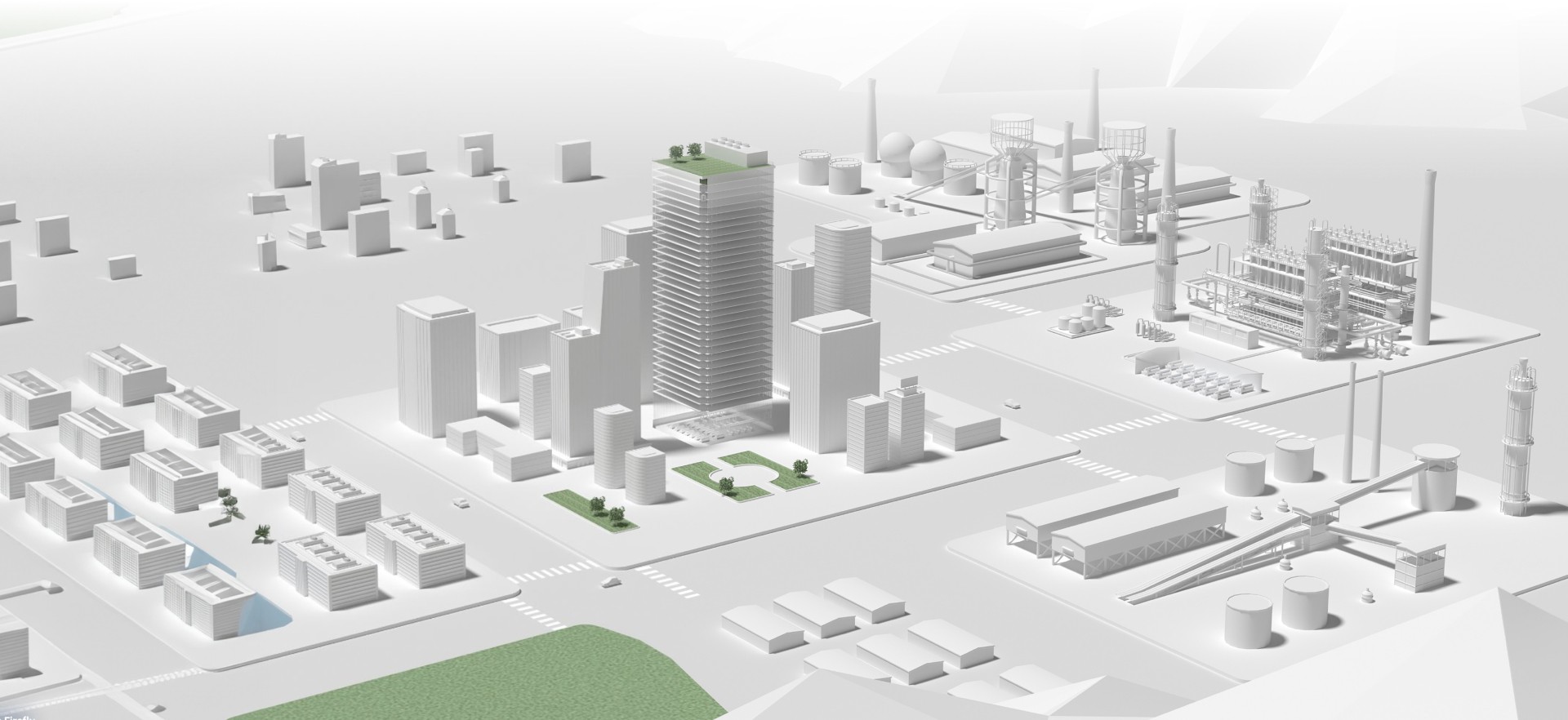

Green industries solutions

According to the report of the International Energy Agency (IEA), industrial energy consumption accounts for 37% of global total energy consumption and 24% of global carbon dioxide emissions. In the compressor and circulating water pump system, using Wolong efficient system solution can improve the system energy efficiency by 20%.

Waste heat recovery system

Steam driven to electrical drive system

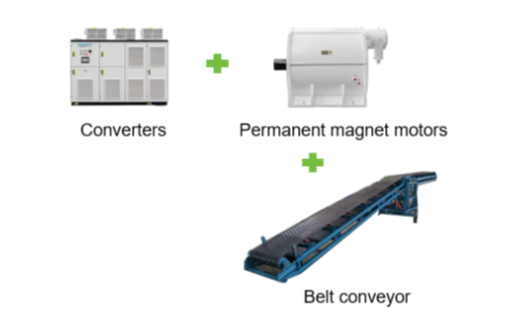

Conveyor system

Grinding system

Circulating water pump system

-

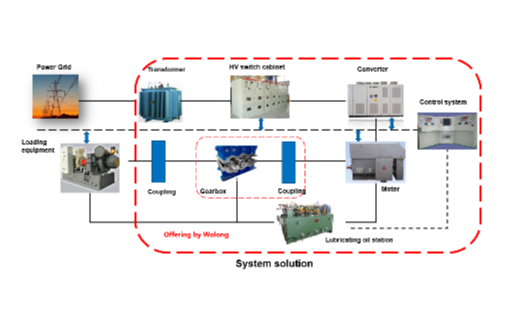

Steam to Electric Conversion

Wolong can provide customized turnkey solutions based on different needs, which can meet the load drive requirements of capacity less than 50000kW, speed less than 12000rpm, and match different load process requirements. System components: motor drive system, including the motor, frequency converter, transformer, and control system. This replaces the turbine and its associated water, oil, and steam systems in the original system's steam turbine unit, resulting in a simpler structure and easier maintenance.

-

Low speed permanent magnet synchronous VFD integrated motor (semi direct-drive)

Integrated, modular design, suitable for underground belt conveyors, winches etc.

-

TYCP5 series low speed direct drive synchronous motors

Capable of achieving S-curve start-up under low-speed heavy loads

-

Low-speed brushless excitation synchronous motors

Featuring a dual-seal strip structure and a large outer diameter rotor design, suitable for Zone 1 and Zone 2 hazardous environments.

-

Main Transport Applications

The main transport application system uses high-efficiency, high-power factor permanent magnet direct-drive motors (permanent magnet drum motors) + variable frequency regulation to achieve high efficiency of the overall device. Through intelligent precise sensing technology and equipment combined with internet transmission, it measures operating status parameters and electrical equipment parameters, provides comprehensive audio and video monitoring and data transmission, and diagnoses and warns of existing faults or potential hazards. This improves the automation control level of transport and the ability to prevent faults.

-

WD200 Series High Performance Vector Type Low Voltage Inverter

WD200 series is a new generation of high-performance general-purpose inverter of Wolong, adopting advanced motor control algorithm, supporting AC asynchronous motor, permanent magnet synchronous motor and synchronous reluctance motor control, featuring high reliability, high performance, strong expansion capability, support for multi-transmission, and easy to set up cabinets.

-

WEPM series VFD permanent magnet synchronous motors

Higher efficiency and power density than induction motors

-

WD1000/WD3000 series variable frequency drive

Applications include metallurgy, pulp and paper, oil and gas, mining, harbor, offshore, marine and power plant industries

-

WD200 Series High Performance Vector Type Low Voltage Inverter

WD200 series is a new generation of high-performance general-purpose inverter of Wolong, adopting advanced motor control algorithm, supporting AC asynchronous motor, permanent magnet synchronous motor and synchronous reluctance motor control, featuring high reliability, high performance, strong expansion capability, support for multi-transmission, and easy to set up cabinets.

-

WEPM series VFD permanent magnet synchronous motors

Higher efficiency and power density than induction motors

-

WIDM100/110 series integrated PM motor

Motor drive integrated product applied in the water pump and fan industries

-

WERM5 series PM-assisted synchronous reluctance motors

Uses ferrite with excellent high-temperature resistance as the magnetic assistance material