Characteristics of AEM FLEX 120 Hydrogen Production Unit

-

Low lead timesReceive your AEM Flex 120 and start your green hydro- gen production within just a few months. We stand for simple planning, and low lead times mean your green hydrogen pilot comes first.

-

Streamlined integrationOur container-free, skid-mounted electrolyser rapidly and seamlessly integrates into your existing energy pro- jects, allowing you to add hydrogen production capabili- ties without extensive site or system modifications.

-

Tailored productionChoose the number of AEM Stack strings to get the exact amount of hydrogen production you need – between 70 kW and 480 kW. If you start small, you will have the possibility to later add electrolyser production capacity.

Condition

-

8:1Adjustment rate

-

12% –100%Operational flexibility

-

5 – 55 °CH₂ outlet temperature

Specifications

| H₂ nominal flow | 25 Nm³/h (53.9 kg/24h) |

| H₂ outlet pressure | Up to 35 barg (507.63 psig) |

| H₂ purity | Impurities: H₂O < 500 ppm, O₂ < 5 ppm |

| H₂ purity with optional dryer | Impurities: H₂O < 5 ppm, O₂ < 5 ppm |

| Nominal power consumption | Beginning of life (BOL) |

| Voltage | 3 × 400 VAC ± 10 % |

| Frequency | 50/60 Hz ± 10 %; THD < 5 % |

| H₂O nominal consumption | 23 L/h (6.08 gal/h)Purified water |

| H₂O inlet quality | Minimum ASTM D1193-06 Type IV or recommended Type II or Type III¹ |

| Hot startup time | 0 – 100% in 100 seconds |

| Cold startup time | 0 – 100% in 20 minutes |

| Dimensions | 3.2 × 2.22 × 2.78 m(L × W × H) |

Typical applications

-

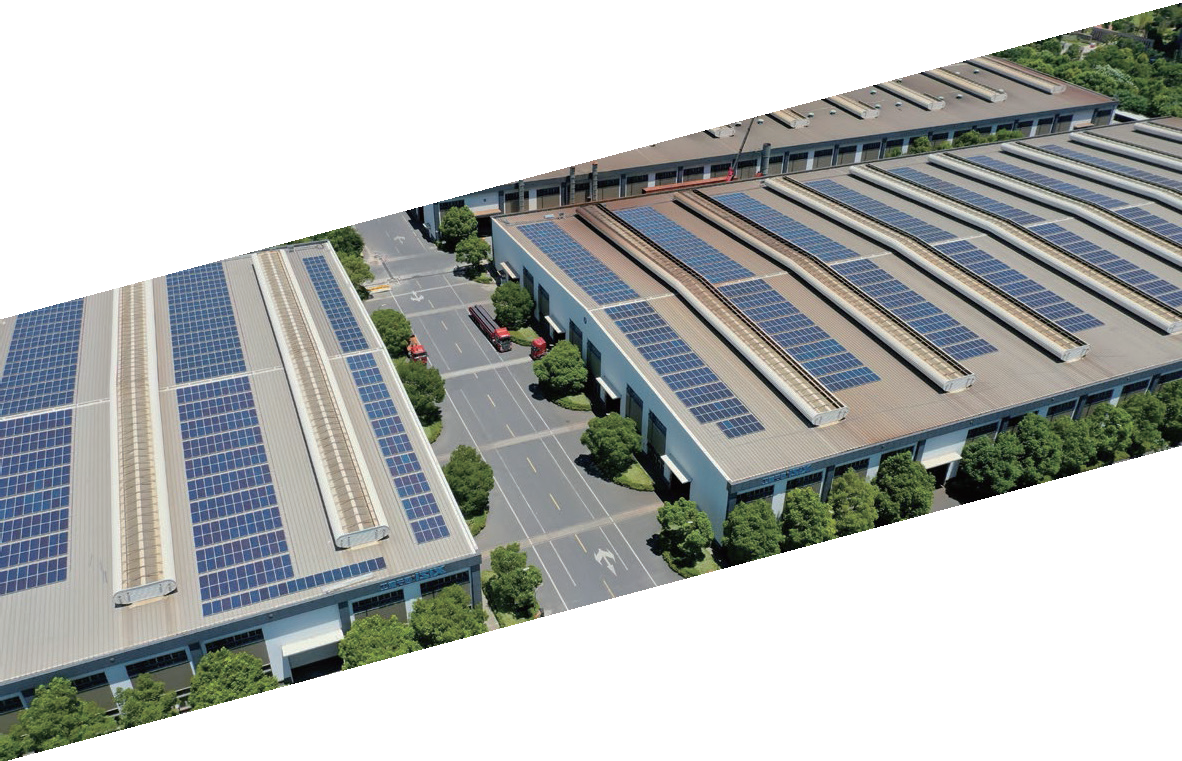

Energy storageFrom peak shaving to long-term storage strategy, this electrolyzer provides a multifunctional solution to produce hydrogen by using excess energy. The company can put its decarbonization and self-sufficiency plan into action; Energy developers get maximum value for power grid and community.

Energy storageFrom peak shaving to long-term storage strategy, this electrolyzer provides a multifunctional solution to produce hydrogen by using excess energy. The company can put its decarbonization and self-sufficiency plan into action; Energy developers get maximum value for power grid and community. -

Industrial raw materialsGreen hydrogen is replacing gray hydrogen as an industrial raw material, which is used to make chemicals such as food, ammonia and methane. Our AEM Flex120 helps industrial enterprises to quickly pilot the production and use of green hydrogen, which opens the door for rapid expansion and comprehensive replacement of gray hydrogen.

Industrial raw materialsGreen hydrogen is replacing gray hydrogen as an industrial raw material, which is used to make chemicals such as food, ammonia and methane. Our AEM Flex120 helps industrial enterprises to quickly pilot the production and use of green hydrogen, which opens the door for rapid expansion and comprehensive replacement of gray hydrogen. -

Industrial heatCompanies that use natural gas as industrial heat are switching to green hydrogen to light their furnaces. AEM Flex 120 allows brick, ceramic and plastic manufacturers to gradually reduce operating costs through gas mixing, and strive to eliminate dependence on fossil fuels and establish their own sustainable development leadership.

Industrial heatCompanies that use natural gas as industrial heat are switching to green hydrogen to light their furnaces. AEM Flex 120 allows brick, ceramic and plastic manufacturers to gradually reduce operating costs through gas mixing, and strive to eliminate dependence on fossil fuels and establish their own sustainable development leadership. -

Demonstration of hydrogen refueling stationOur flexible electrolyzer is specially designed to improve efficiency and expandability, and can make use of fluctuating renewable energy to produce hydrogen on site to meet the needs of pilot projects and the next stage of growth. Reduce dependence on external suppliers and pave the way for a sustainable hydrogen-driven future.

Demonstration of hydrogen refueling stationOur flexible electrolyzer is specially designed to improve efficiency and expandability, and can make use of fluctuating renewable energy to produce hydrogen on site to meet the needs of pilot projects and the next stage of growth. Reduce dependence on external suppliers and pave the way for a sustainable hydrogen-driven future.